Technology

More than twenty years ago, FP-propeller made the in-flight variable pitch hub for propellers to be used in Micro-Lights. The machining of the hub parts, carried out in numeric control station of last generation, assures the best of mechanical precision in the pitch motion. Today, different hub models are available, two-blade and three blade, in order to obtain the best coupling with the blades of different size.

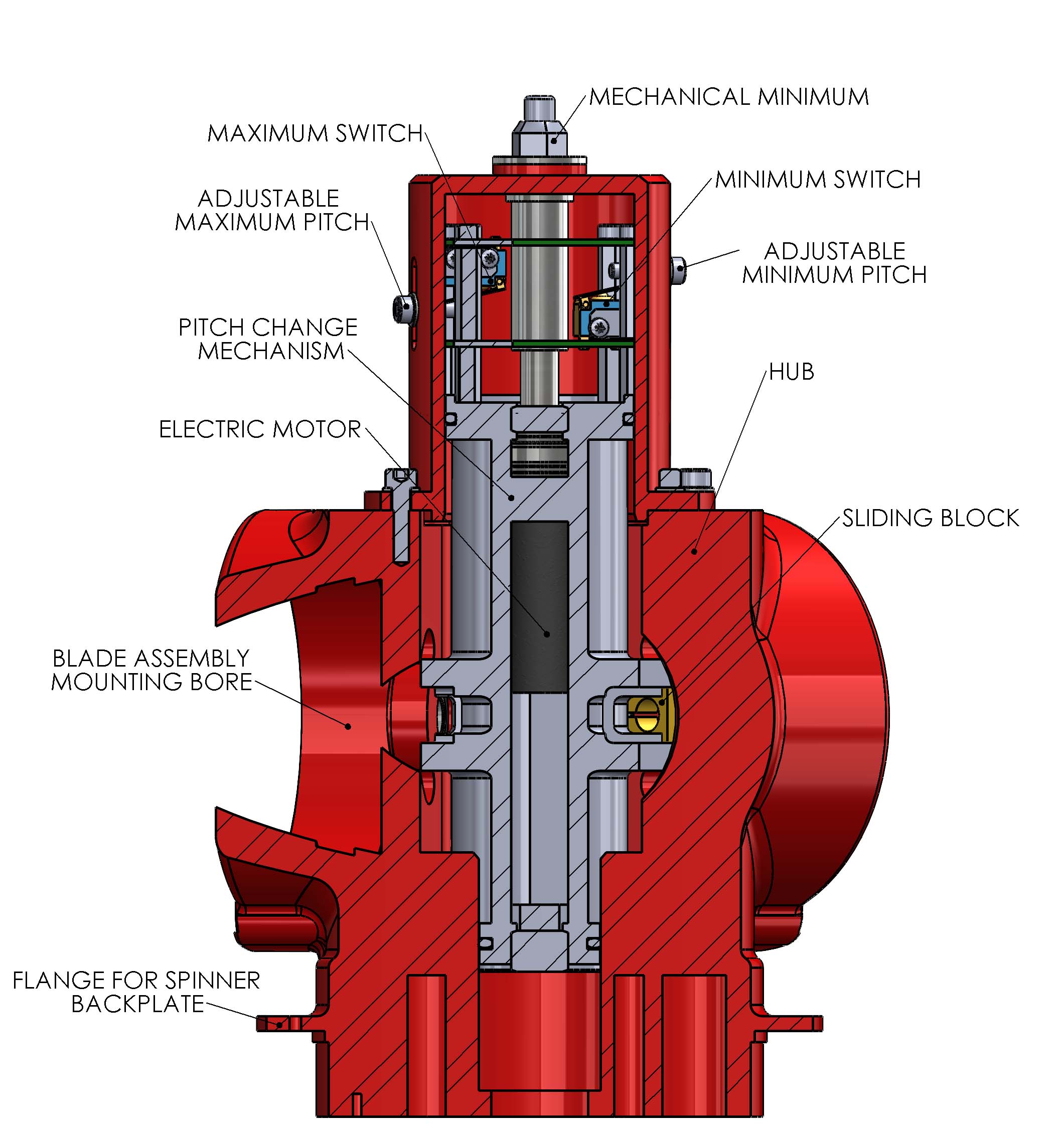

Electrically driven Hub

The blade pitch variation is achieved by electric servo-motor. The servo-motor is made under our own project and is produced for FP-propeller exclusively. The primary characteristics we done to our servo-motor are:- Guaranted and tested functionality up to 3000 rpm of the propeller

- Epicyclic gearbox entirely made in metal

- Long durability (>2000 hr in the range -30°C +50°C)

- Absolute reliability of the functionality

Main Features:

- safety factor higher than 10

- mechanism motion over bearings, in order to eliminate wear and tear

- pitch range limits, upper and lower, adjustable

- safety block for the lower pitch limit, in order to prevent in any case the “reverse”

- manual tuning of the blade pitch in the case of electrical breakdown

- TBO of 2.000 hours

- Power supply: 12VDC or 24VDC

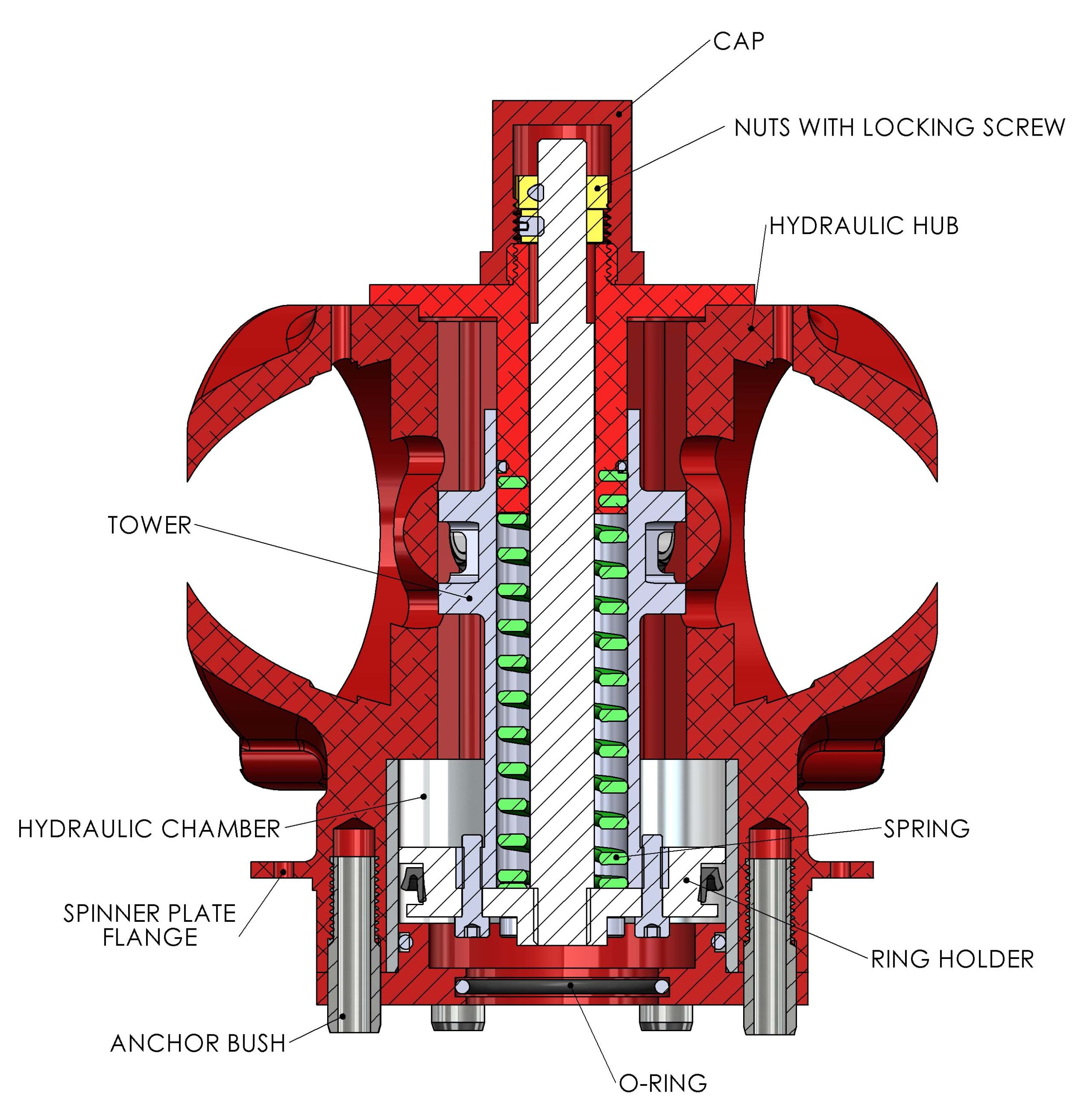

Hydraulically driven Hub

The electric motor in the hub was replaced by the hydraulic piston. The hydraulic version of the hub was realized for the pilot who likes this solution. In particular, the hydraulic piston we made is absolutely free of oil leakages on the sealing parts. The propeller pitch driving can be obtained hydraulic constant speed governor (i.e: Jihostroj).Main Features:

- safety factor higher than 10

- mechanism motion over bearings, in order to eliminate wear and tear

- high speed in the blade pitch variation

- pitch range limits: lower, adjustable

- TBO of 2.000 hours